Our new proprietary membrane technology brings you enhanced product yields, high capacity, great selectivity, and less fouling during applications such as:

- Primary recovery of recombinant biopharmaceuticals

- Vaccine purification and concentration,

- Debris removal (post-centrifugation)

- Bacteria separation in fermentation broths

- Cell harvesting/cell washing

- Bioindustrial cell separation

- Macromolecule concentration and diafiltration

- Clarification, Dia-filtraiton and Concentration of Monoclonal Antibodies

Hollow Fibers and primary recovery in Biopharmaceutical Filtration

Many cell clarification processes employ centrifuges, single flow cartridges, and plate and frame depth filters, or combinations for cell removal prior to chromatographic separations. Due to incomplete removal of cells or cell debris in the product streams, down-stream chromatography columns can become fouled by these particulates leading to high pressure drops, unsatisfactory purification, and expensive premature failure of the chromatography media.

Our hollow fiber membranes are recommended for removal of cells and cell debris prior to chromatography separations, leading to extended service life and reduced cost of the chromatography columns. The low protein binding antifouling membranes excel at resisting fouling from anti-foam materials typically found in cell broths in these product streams. Reduced fouling leads to higher product transmission resulting in improved yields. Hollow fibers are also a very cost effective format for concentration / diafiltration of dilute biomolecule solutions and are ideal in processes where single use membrane devices are desired. Our antifouling membranes provide an advantage in cleaning during membrane recovery leading to:

- Reduced chemical consumption

- Less system downtime

- Longer service life

- Reduced risk for cross contamination

- Minimized batch-to-batch variation

When your results need to be right, our membranes consistently delivers the right material

Our membranes are manufactured using a unique combination of modified polyethersulfone (PES) and a proprietary spinning process. The result is a filter that exhibits exceptional chemical and physical properties. The antifouling properties of the membrane make it ideal for most applications involving lipids, as well as antifoam agents commonly used in fermentation broths. PES also meets the strictest regulatory requirements of biopharmaceutical processing.

|

|

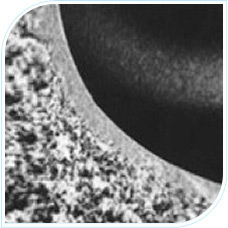

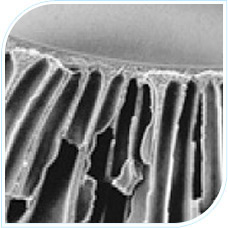

| Figure 1. Our void free structure provides a mechanically strong, more robust membrane with extended service life and reduced cost of ownership. | Figure 2. Many traditionally manufactured membranes feature a finger-void construction, as shown here, which |

The right performance

Our membranes have a unique void-free structure, which is significantly stronger than competitive "finger void" membranes (see Figures 1 and 2). This structure results in a stronger cartridge with a longer surface life and significantly lower risk for fiber breakage and product loss. The membrane also has a very high water and process permeability, resulting in higher process capacity and lower cost of ownership.

Figure 3. Scale-up made simple with a full spectrum of filters designed to take you from bench top to production. Membrane area available from 50cm2 till 10 m2 |

The right format Our HF filters accommodate particle-loaded process streams with significant improvement over traditional screen and open channel cassettes plate-and-frame systems, and spiral-wound cartridges. Rather than relying on retentate screens that risk particle entrapment, Our cartridges avoid dead spots altogether with an open flow path. This construction also makes cleaning and sanitizing easier and more effective. This provides a superior format for the upstream clarification of many biopharmaceutical processes, and is also well suited for clarification and concentration operations during vaccine production. The cartridge construction makes cleaning and sanitizing easier and more effective. In addition, by design, Our filters provide a straightforward scale-up process, going from laboratory volumes to pilot-scale to full manufacturing without a change in materials, membrane properties, or fluid paths (see Fig. 3). |

And the selection that helps you make the right choice too.

Our product offering is based on 3 fluid path lengths -12" - 24" - 41"- that are consistent throughout the entire product line. This enables easy and reliable scale-up and scale-down of you process, by choosing between three different hollow fiber cartridge diameters: ½" (13mm), 1.3" (33mm), and 3.5" (89mm). Molecular weight cut-offs (MWCO) that range from 3K to 750K and in pore sizes from 0.1 µm, 0.2 µm, 0.45 µm, and 0.65 µm.

Explorer

The Explorer series is recommended for membrane screening and laboratory volumes up to 15L.

Investigator

The Investigator series is ideal for process development and pilot applications with 10L - 100L process streams.

Bioproducer

The Bio Producer series is our large scale high capacity hollow fiber cartridges for product batches up to several thousand liters. The higher membrane flux (flow rate/unit surface area) and optimized hollow fiber packing density in our cartridges ensures larger process capacity and more economical systems with smaller footprint.

Re-Use Series

For those applications where re-use is acceptable, the ReUse cartridges are ideal for concentration and diafiltration of peptides, enzymes, monoclonal,antibodies and other proteins and vaccines as well as harvest and cell clarification.

The ReUse cartridges utilize our well accepted antifouling, low binding, modified ployethersulfone (m-PES), membrane and are offered in molecular weight cut-offs (MWCO) that range from 3k to 750k and in pore sizes from 0.1 µm, 0.2 µm, 0.45 µm, and 0.65 µm with Lumen ID's of 0.5 mm, 1.0 mm and 2.0 mm. The antifouling properties of the m-PES membrane typically provide superior process flux and higher product recovery than do most other cross flow devices.

Steamer Series

The Steamer is an autoclavable, gamma irradiated, re-usable hollow fiber cartridge made with our low binding, glycerin free modified PES membrane (m-PES) with provides process flux and product recovery that exceeds other cross flow devices. Steamer cartridges are ready to use without ant pre-rinse or sanitization, or can be autoclaved as is, or in an assembly.

The Steamer hollow fiber cartridge products are in most applications superior to conventional techniques, like centrifugation, depth filters of UF/DF cassettes.

Green Series

The green cartridges offer a true single use crossflow system that provides, The Green cartridges utilize our antifouling, low binding modified ployethersulfone membrane (m-PES) which provides a process flux and product recovery that exceeds other crossflow devices.